Ever since the Home Insurance Building, the world’s first skyscrapers, went up in Chicago in 1885, steel has been a major component in commercial building construction. Skyscrapers are simply not possible without steel.

▲ Home Insurance Building, the world’s first skyscraper (Lifespan: 1885 ~ 1931)

But what about for residential construction? Steel is definitely used to build our houses – wall panels, pipes and all – but are they simply design components? If not, how crucial are they?

In the past, builders did use to prefer wood over steel to frame residential buildings. However, because of its durability, steel is gaining more popularity.

What are some of the strengths of steel for residential construction in functionality as well as aesthetics aspects? What potentials does POSCO see for steel as residential construction materials? POSCO Newsroom reports.

l Steel Beauties around the World

Although wood has been popular as structural materials for residential construction, here are some of the advantages that steel has over wood. Steel has a higher strength to weight ratio than wood, which means steel components are stronger without adding much weight.

This is what makes steel structures stronger than wood, which is very attractive in areas prone to tornadoes, earthquakes, and other natural disasters. Steel is also fire- and termite-resistant, making it more durable than wood. To promote the strength of steel as residential construction materials, the World Steel Association (worldsteel) introduced ten houses as part of its #lovesteel campaign. Here are some of the examples.

(1) Corten House in Belgium

Located in Kontich, Belgium, the house was completed in 2013. The steel used by the firm DMOA House for the Corten House has plenty of assets to fall in love with, for its structural strength, pureness as well as the warm color of rust. The versatility of steel allows it to shape in any way.

▲ Courten House (Photo by: Luc Roymans)

The owner of the Corten House says, “We were especially charmed by its deep rusty red color, which intensifies around sunset. While being a raw material, Corten steel also brings a vivid ambiance. The house combines a unique and contemporary style with warmth and coziness.”

(2) Flip House in San Francisco, USA

Designed by Fougeron Architecture, this 2013 Residential Architect Merit Award winner is a flip of tradition San Francisco home.

▲ Flip House (Photo by: Joe Fletcher)

Like many San Francisco homes, the original house poorly integrated its many levels with each other. Instead of selecting a new site or building a completely new home, the Fougeron Architecture reinvented and remodeled the house to suit the unique needs of a growing family in a dense urban culture. The glass panels that create the undulating curtain walls of the facade fills the rooms with natural light, allowing a great view of San Francisco – the thin steel frame made it possible to contain the glass panels.

(3) Residence at Alibag in Mumbai, India

Situated on a steep hill with Mumbai in the distance, the steel and concrete used in this design defy conventional approaches. The architect chose to deconstruct cuboid that is tilted and suspended over the ground giving the impression of a floating house. With the steel structure, the designers at the Malik Architecture successfully created concrete planes making contact with the ground, while steel floats above it.

▲ Alibag Residenc (Photo by: Malik Architecture)

All in all, using structural steel provided a column-free, and flexible use of interior space. At this residential house in Alibag, structural steel has been used in its purest form, a major aesthetic element in the overall composition.

(4) Kloof Road House in Johanenesburg, South Africa

Located at the foot of a nature reserve in Bedfordview, Johannesburg, black steel is used extensively for the house’s exterior, creating a distinct bland with the soft green colors of the garden and white-washed walls.

▲ Kloof Road House (Photo by: Nico vander House)

Steel and glass are prominent materials used in Kloof Road House and have been uniquely integrated into the design, from the boundary wall all the way into the interior details. The angled columns and steel beams pierce the double volume space. These structural elements were designed to appear sculptural, while the sculptures on display simultaneously compliment the structural components of the building.

(5) Moebius House by Tony Owen Partners

A suburban house overlooking Sydney Harbour, the complex curving structure is made possible by pre-cut steel-framed panels. The design is a good example of ‘liquid architecture’ whereby projects are designed parametrically using 3D modeling software.

▲ Moebius House (Photo by: Tony Owens Partners)

ㅣSteel Houses Made by POSCO

The houses introduced by the worldsteel proved the value of steel as structural material for residential construction, well beyond design components. Nonetheless, one of the major drawbacks to using steel in residential construction is price. It is still challenging to find contractors to build residential homes with steel framing. Compared to wood, steel homes cost about 14 percent more to build and require more time to complete.

The benefits of steel, however, seem too good to ignore. POSCO, who has been well aware of steel’s potential as residential construction material, took on projects to help curb the notion that steel house is expensive.

In 2018, at the heart of Seoul’s Seodaemun district, POSCO built a youth share house Nuri, made of steel, for people who are just starting out in their career. Nuri not only provides a place to nurture young people facing housing insecurity, but also uses five POSCO technologies that are ideal for structural safety, durability and energy saving.

For the construction of Nuri, POSCO used the rust-free and corrosion-resistant PosMAC. In addition, PosART (aka POSCO Artistic Steel) decorates the lobby of the Nuri, symbolizing the young residents’ passion and dream sprouting and springing up there. PosART broke ground and became commercialized last year as Korea’s first high-resolution inkjet print – PosART is also semi-permanent.

▲ PosART at POSCO Steel House, Nuri

With the company’s own steel materials, POSCO also builds and donates steel houses for the underprivileged communities – both POSCO employees and Beyonders (POSCO’s global youth volunteer corps comprised of community-minded university students) actively participate. Ever since the company broke ground for its first steel house in 2009, POSCO donated more than 50 houses to the communities in need.

Steel is also in use as the major source of residential construction material for POSCO’s Steel Village. Just like steel houses above, POSCO’s Steel Village project is also a community-oriented project where POSCO’s technology and materials are put into good use.

Since 2014, POSCO built more than 104 houses – and steel bridges – in Vietnam’s underprivileged communities. This year, POSCO is undertaking the Steel Village Project in Indonesia Cilegon district where POSCO’s integrated steel mill PT.KRAKATAU POSCO is located.

l Steel Buildings Last More Than 100 Years

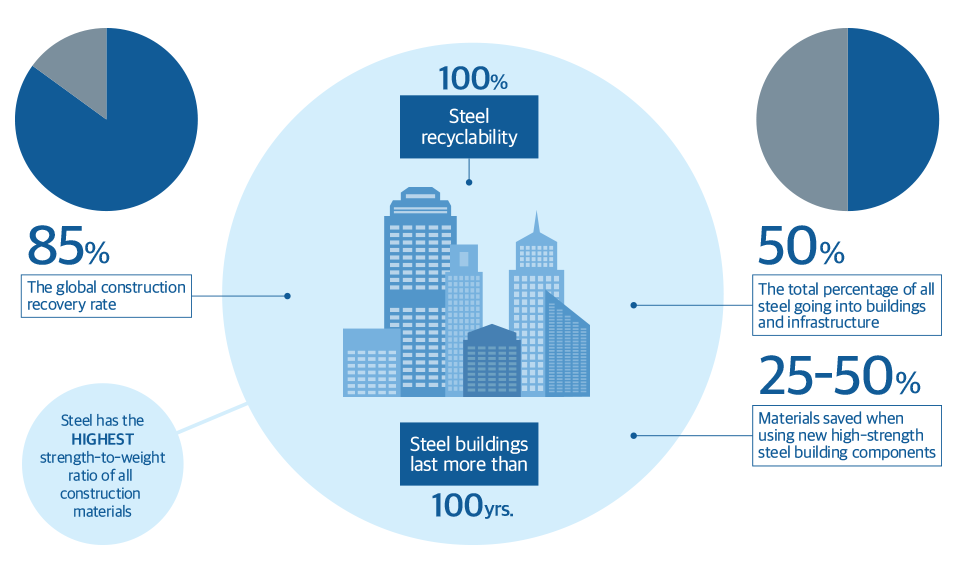

To sum up, here are some key statistics of steel use in construciton:

▲ Steel use in construction: statistics – sourced from worldsteel and reproduced in POSCO Newsroom

More than 50% of all steel goes into buildings and infrastructure – and the global construction recovery rate for the 100% recyclable steel is at 85%. Not only that, thanks to new high strength steel, building components require 25-50% less material.

Steel buildings last more than 100 years – that’s why steel is one of the major structural materials for so many commercial buildings whilst establishing itself as crucial design components in residential buildings.

The strength of steel as residential construction materials is getting recognition and its use is likely to be expanded. As a steel company, POSCO will continue the journey to promote the potential of steel in a way that can help contribute to the community it serves.