manufacturing cost competitiveness, and safety in various industries.

In particular, as the electric vehicle market expands and the lightening of car bodies becomes an issue,

the application of multi-materials is actively being carried out.

Therefore, the POSCO Steel Solution Research Center, Automotive Material Research Center, and Automotive Material Marketing Office are spurring the development of steel-centered multi-material technologies and demand. We introduce POSCO’s new challenges in preparation for the upcoming multi-material era as follows.

![]()

Multi-material means combining heterogeneous materials in the unit of materials or parts. By reinterpreting and combining existing materials, optimal performance is realized, which is difficult to achieve with single materials. By combining conventional materials such as steel, aluminum, stainless steel and plastic for the new performance that has not existed in the past can be obtained.

Traditionally, heterogeneous materials have been combined mechanically using bolts and rivets. However, this has disadvantages such as increased weight and processing costs, so a method of bonding materials such as steel and nonferrous metals by applying heat and pressure or attaching them with new adhesives is used now.

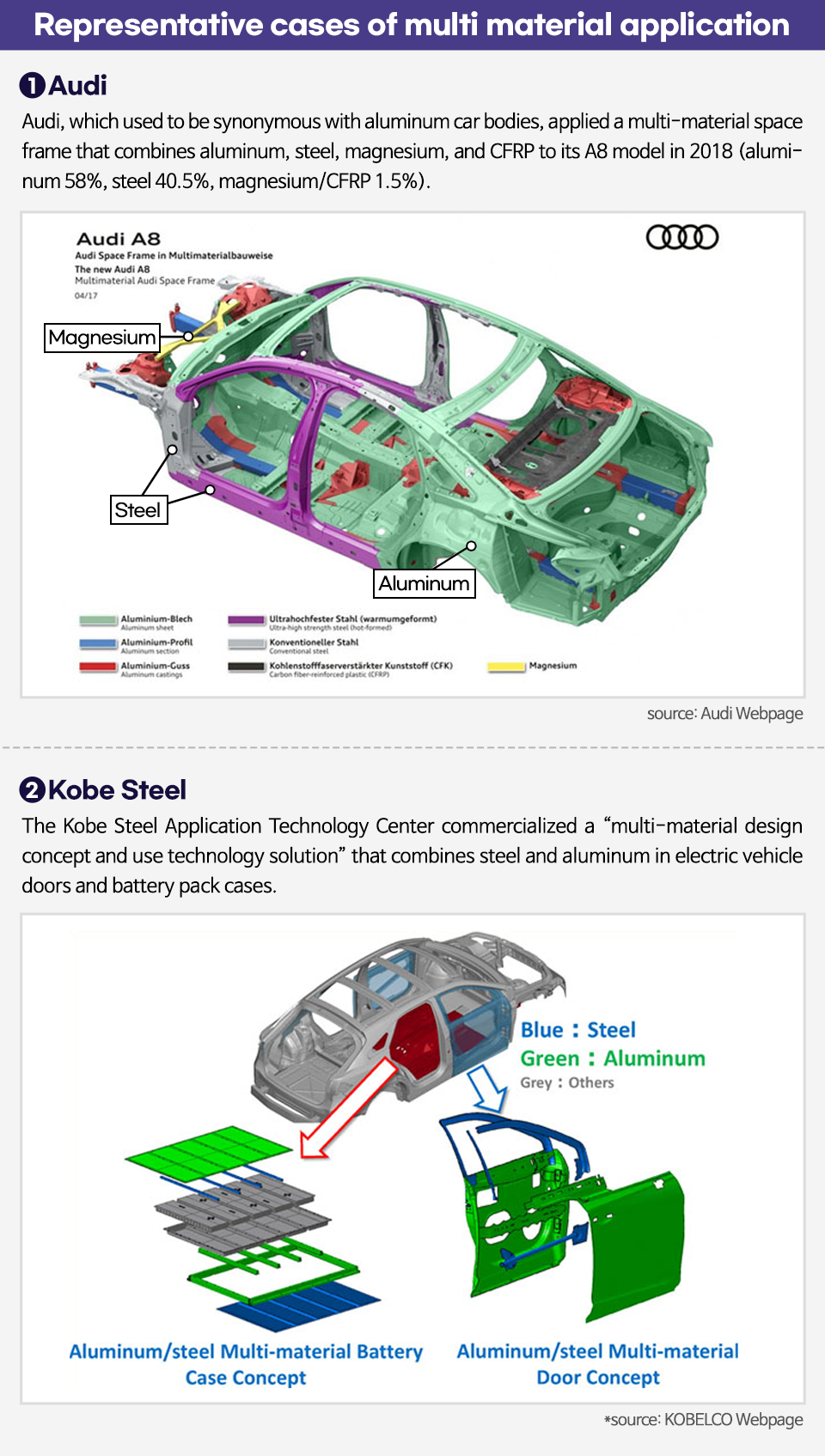

![]()

Recently, interest in multi-materials that have strengths in △weight lightening, △manufacturing cost, △safety, and △design has been rising in various industries. Among them, automotive parts use multi-materials the most, and the electrical and electronic STS product market also actively applies them.

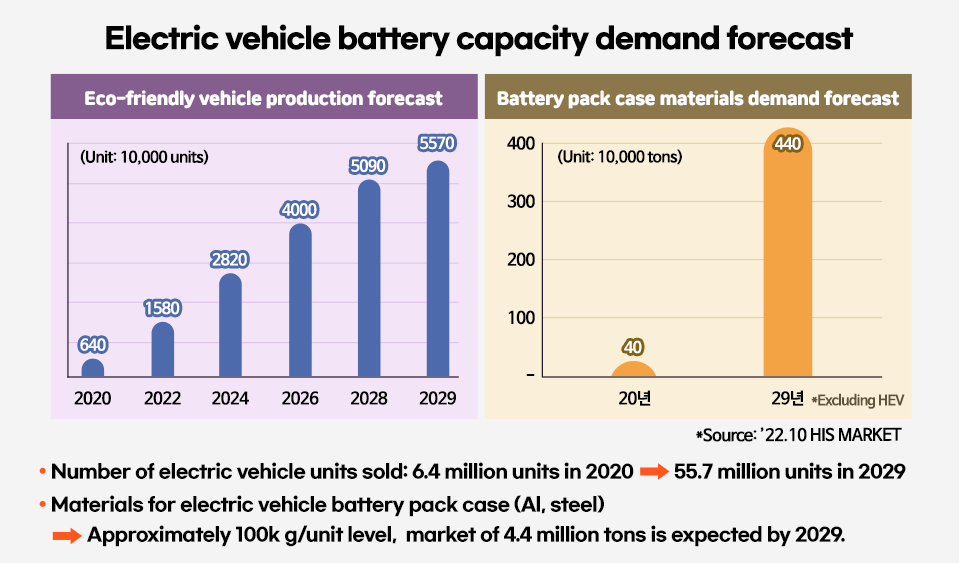

In particular, as the production of electric vehicles has expanded, the need for lighter car bodies is continuously increasing. This is because consumers care about how far the car can go on a single charge when they purchase electric vehicles. That is why carmakers increase mileage by using aluminum, which is light, although it is three times more expensive than steel. This means lightweight materials are gradually replacing steel in the eco-friendly vehicle industry.

As demand for lightweight materials such as aluminum is increasing due to the paradigm shift in the automobile industry, it is emerging as a major threat to the steel industry. Steel companies should also find ways to coexist with competing materials and secure demand in new markets.

To maintain the demand for steel, there is a need to have differentiated competitiveness by supplying high performance steel materials or develop multi-material products that combine steel and lightweight materials, such as aluminum.

For this reason, the POSCO Steel Solution Research Center and Automotive Material Research Center are developing steel-centered multi-material product technologies and solutions. Along with this, the Automotive Material Marketing Office is proactively preparing for the growth of the electric vehicle market by suggesting multi-material solutions to customer companies and developing demand based on the market needs. Let’s look at POSCO multi-materials in more detail.

![]()

1) Multi-material Battery Pack

The battery pack for electric vehicles, which consists of a cell-module-pack, is the heaviest as a single part, and a key factor that decides the performance and safety of vehicles. Performance can be enhanced when mileage is increased by making “lightweight” vehicles, while safety can be ensured by making it “strong” to minimize the affect of external impacts. That is why multi-materials such as steel, aluminum, and plastic are applied the most in the battery pack.

POSCO developed the multi-material battery pack to resolve the technical contradiction of being lighter and stronger at the same time. That is a concept where POSCO combines aluminum with steel to capture the advantages of the two materials at the same time.

The POSCO type multi-material battery pack concept maximizes synergy by combining the strength of steel with the lightness of aluminum. By designing with aluminum to endure local collision energy and ultra-high strength steel to endure overall collision energy, weight was improved by more than 10% and performance by about 20% compared to existing steel battery packs. In addition, manufacturing costs decreased by more than 20% compared to aluminum battery packs with the same weight.

▲ Concept of POSCO Battery Pack for Electric Vehicle (PBP-EV). From left, first-generation steel concept (2018), second-generation steel concept (2020), and the 2.5th-generation multi-material concept (2021) model.

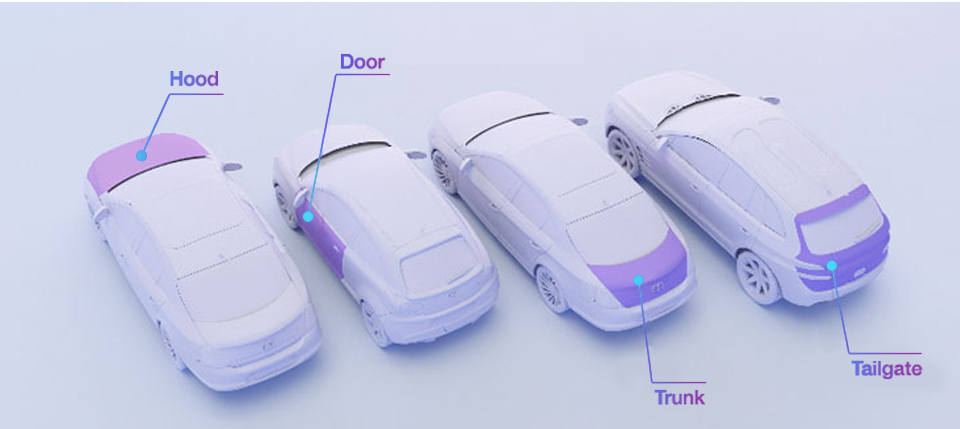

2) Multi-material Vehicle Closure

Recently, the use of aluminum has been increasing to lighten the weight of the vehicle’s closure components (hood, door, trunk and tailgate).

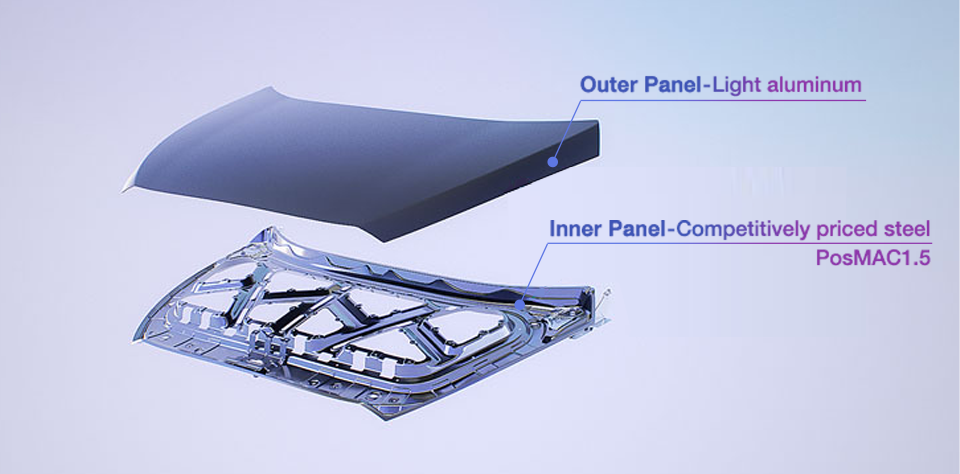

POSCO applied aluminum to the outer panel of the closure and ultra-thin steel for inner panels. This is to compensate for the “excellent moldability” and “cost competitiveness” of steel that aluminum doesn’t have. However, if steel and aluminum directly contact each other, corrosion is likely to occur. In particular, closure parts are more vulnerable to corrosion because they are exposed to the exterior of the vehicle. To solve this problem, POSCO applied PosMAC, which has excellent corrosion resistance, to the inner panels.

3) Multi-material composite steel sheet, “sandwich sheet”

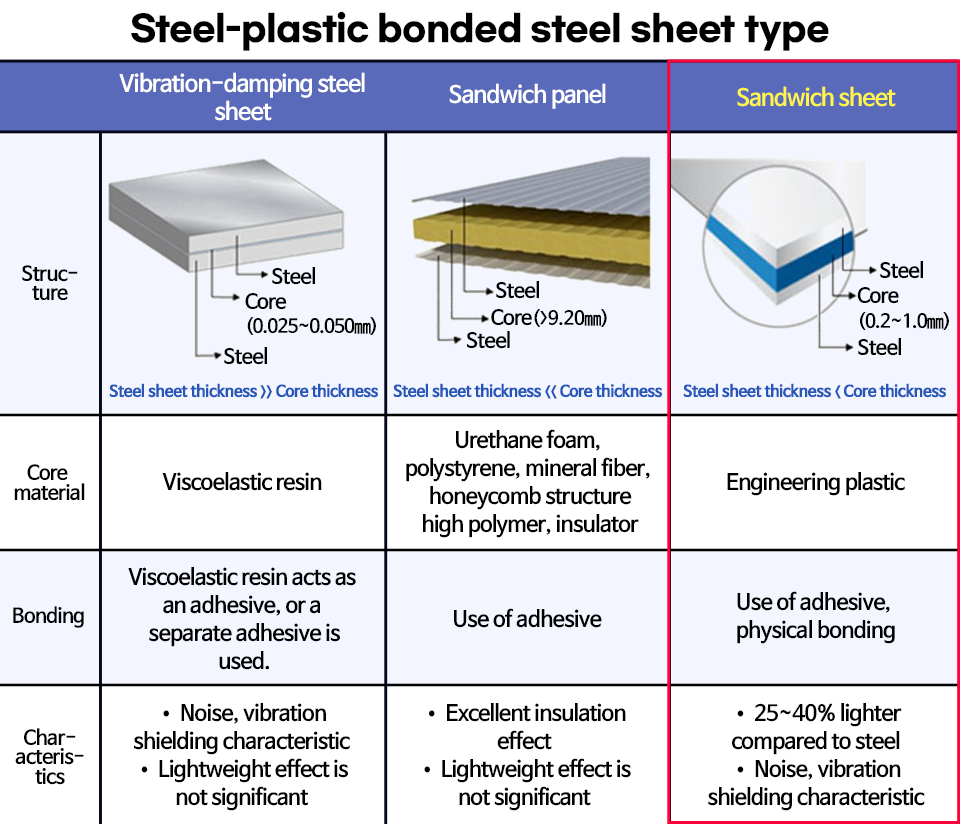

Sandwich-type steel plates are made to have a three-layer structure by inserting various types of materials between two sheets of steel like a sandwich. By type, it can be classified as ①vibration-damping steel sheet, ②sandwich panel, and ③sandwich sheet.

Currently, POSCO is spurring the development of lightweight sandwich steel sheets. Steel is used on the top and bottom and plastic in the center, which is similar in thickness to steel while maximizing the lightweight effect. Also, if the existing processing method is applied, noise and vibration can be reduced.

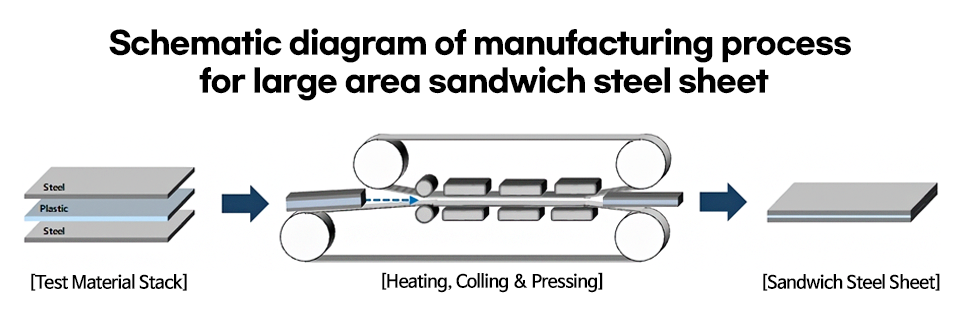

The bonding power of lightweight sandwich steel sheet was secured naturally without using a separate adhesive with POSCO’s own new coating technology by selecting the optimal eco-friendly low-carbon plastic. In addition, through plastic properties and heat fusion technology, POSCO plans to introduce facilities that can manufacture 1200-mm-wide large area sandwich steel sheets and make parts, while producing prototypes in applicable sizes.

As a result of applying sandwich steel sheet with these strengths to 31 steel parts of a car body POSCO developed, it was confirmed that it has a weight reduction effect of 34%.

4) Multi-material Heterogeneous Integration and Corrosion Science Technology

[Heterogeneous Integration Technology]

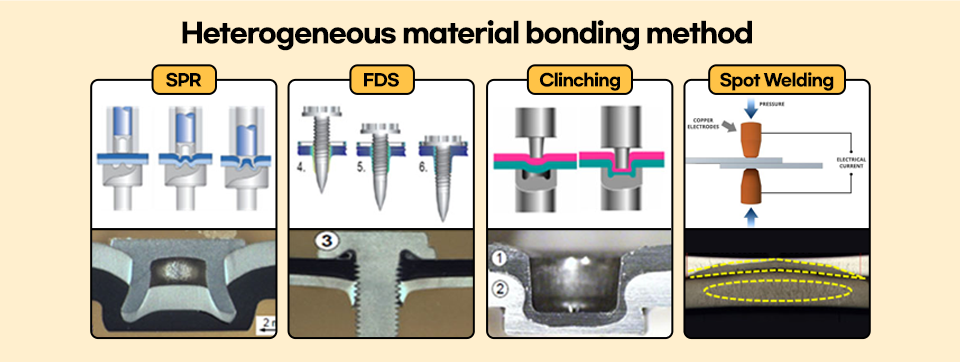

Bonding between heterogeneous materials is difficult with conventional methods such as spot/arc welding due to differences in material characteristics, so mechanical bonding technologies such as self-piercing rivets (SPR) and flow drilling screws (FDS) are generally applied. However, mechanical bonding technologies have problems such as facility investment, weight increase, and structural constraints.

To solve this, POSCO developed fusion bonding technology that uses existing methods such as spot welding and mechanical bonding technology for 1.5GPa class ultra-high strength steel and conducted a performance evaluation with domestic carmakers. Through this, strength equivalent to general bonding technologies for mass production could be confirmed.

In addition, a heterogeneous material brazing bonding technology is being developed with a customer company to replace the cooling plate of an electric vehicle battery pack with a heterogeneous combination of Al-STS from the existing Al-Al single combination.

[Corrosion science and technology]

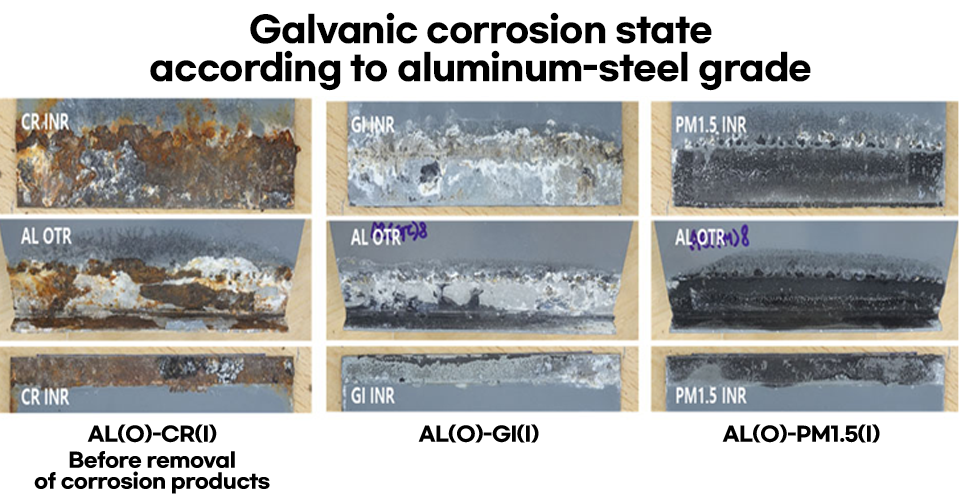

In the joining of multi-materials, a combination of “galvanic corrosion”* occurs between two materials and “crevice corrosion” occurs between narrow crevices. In a corrosion test with the joints of various steel sheets, the research center confirmed that PosMAC 1.5 steel sheet was the most effective material to reduce galvanic corrosion when its is bonded with aluminum. Also, POSCO is developing a multi-material adhesive material with a function of preventing the inflow of moisture and corrosive substances through crevices with a specialized company.

*Galvanic Corrosion : Corrosion caused by the movement of electrons when heterogeneous metals are in contact with each other and there is a potential difference.

![]()

Our attitude toward the era of multi-material strategy

The era of the multi-material strategy has already begun. Major manufacturing powerhouses such as Japan and Germany recognize the value of conventional materials such as steel rather than finding new materials, and are cultivating an industry that develops multi-material technologies based on demand. In particular, the demand for multi-materials is increasing in core industries such as vehicles and electrical and electronic products, and material companies can secure future competitiveness only when they occupy the market with matchless technologies and differentiated solutions.

POSCO plans to maintain powerful leadership as a material company by ceaselessly developing steel-based multi-material technologies and solutions and moving toward the multi-material market.